Nanomolding technology

01

Multi head glue spraying equipment rolls at a constant speed · Point needle glue application on the surface · Avoid surface blemishes

The master pattern is derived from a 1‰ data collection sample, using nano atomic effects to decompose the base paper,

By combining 3D multi-dimensional coatings, a natural surface texture is constructed to achieve a more high-end home space experience

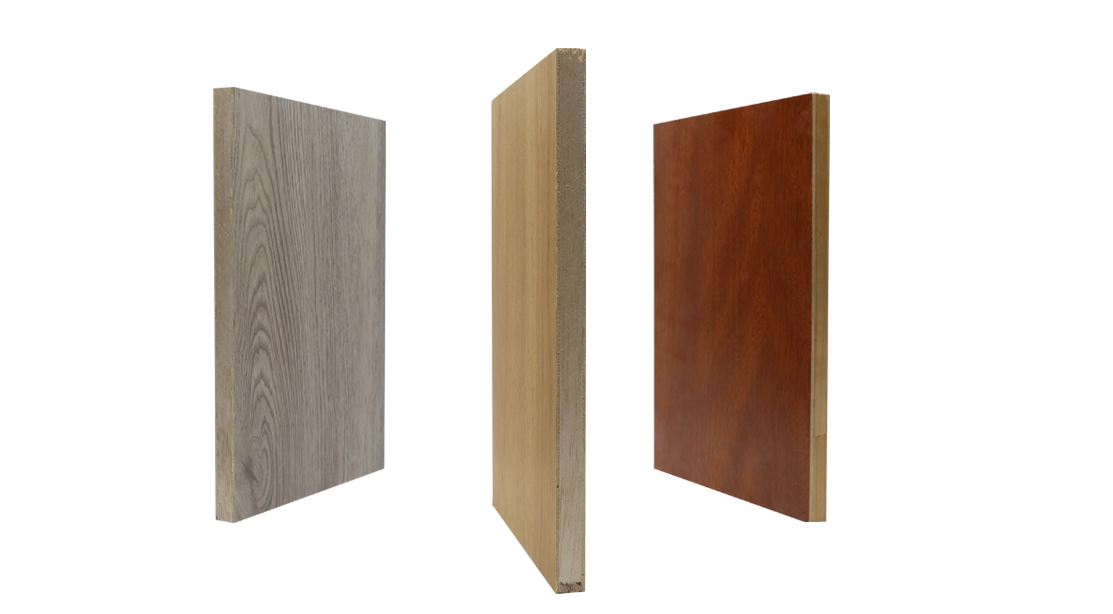

Ultra flat pressing technology

02

Integrated line and surface, sand grinding treatment, delicate and smooth without pits, seamless pressing and pasting

Adopting imported double-sided intelligent sanding machine, scientifically programmed 360 degree seamless line and surface integrated sanding treatment,

Fully achieve a smooth and flawless surface of the product, thus achieving seamless lamination.

Uniform adhesive rolling coating technology

03

Multi head glue spraying equipment rolls at a constant speed · Point needle glue application on the surface · Avoid surface blemishes

The fully automatic multi head glue spraying equipment rolls at a constant speed throughout the entire process, with a needle type 0.01mm3/s glue application surface,

Uniform spraying of no time neutral and blank blind spots, adhesive particles bonding the board core and decorative materials, and effectively avoiding decorative defects.

Ultra high temperature and high pressure compression technology

04

High temperature locked moisture content, solidified atomic structure, and high-pressure constant product performance

Constant temperature control locks the moisture content of logs at 8-12%, synchronously solidifying the atomic physical structure inside the board,

A 200 ton compression device is used to create products with anti-corrosion and anti deformation properties.

Ultra high temperature instant purification process

05

Fully enclosed instant rapid heat treatment · E0 environmental protection standard

High temperature constant quantity timed purification process, fully enclosed instant high-temperature rapid heat treatment,

Forcefully extract harmful substances from the interior of wood to meet E0 environmental standards

Formaldehyde free polymerization process

06

Polymer monomer linkage, high temperature and high strength digestion, benzene formaldehyde release meets environmental standards

200 ℃ polymer with high temperature resistance and high-strength chemical treatment for benzene,

A small amount of impurities inside the product are formed through monomer linked synthesis, and then stored for a long time to ensure that the product meets environmental standards.